- PVA TePla

- Technology Fields

- Quality Inspection

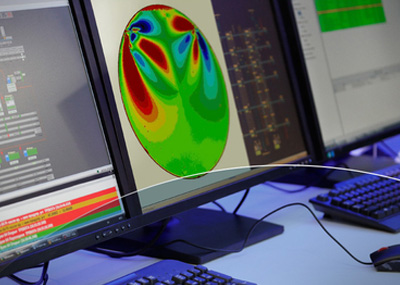

Our SIRD systems enable

- Reliable monitoring of epitaxy reactors with a particular focus on the wafer edge region

- Monitoring and optimizing of high-temperature or abrasive processes in the manufacturing of silicon wafers for semiconductor components, solar cells, and other materials for opto-electronic components

- The evaluation of global stress or localized defects both on the entire silicon wafer as well as in defined areas

Learn More about the Technology

Metrology & Plasma Solutions

With our VPD method (Vapor Phase Decomposition), we enable

- Reliable analysis of wafers and semiconductor components to a concentration range of 107 at/cm²

- Etching of the wafer surface with gaseous hydrogen fluoride (HF) to ensure absolute purity and safe handling of the HF gases.

- Collection of contamination and concentration in a small droplet using the PAD scan. This module offers various scan patterns, advanced handling of droplets, and preparation of the subsequent analysis.

- Preparation for the Analysis

Learn More about the Technology

Metrology & Plasma Solutions

Our SAM systems and software provide options for

- Non-destructive testing of opaque (optically non-transparent) materials for quality and process control as well as for research applications

- Fully-automated detection of cavities, voids, bubbles, inclusions, and delamination—particularly suitable for wafer inspection, bond checking, and MEMS inspection.

- Combinations of ultrasonic microscopy and optical microscopy—particularly suitable for research and industrial applications

- Analysis and evaluation of specific customer samples

Learn More about the Technology

Scanning Acoustic Microscopy